Chemical Composition

316 Stainless Steel

Carbon: 0.08% (Max)

Manganese: 2.00% (Max)

Silicon: 0.75% (Max)

Phosphorous: 0.045% (Max)

Sulfur: 0.03% (Max)

Chromium: 16%-18%

Molybdenum: 2%-3%

Nickel: 10%-14%

|

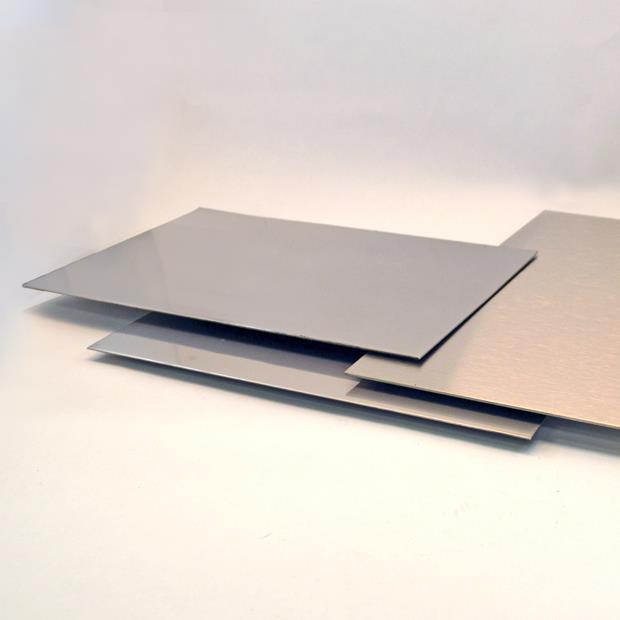

316 Polished Finish Stainless Steel

316 and 316/316L stainless steel are an austenitic chrome nickel steel with superior corrosion resistance to that of other chrome nickel steels. Widely used when exposed to chemical corrodents, as well as marine atmospheres. 316 stainless steel is generally considered non-magnetic, but can become magnetic when cold worked. In grade 316/316L stainless steel, the carbon content has been lowered to .03% max. for corrosion resistance at heat affected zones from welding. This material has been polished to provide a better surface finish.

Properties

Grade 316

Tensile Strength: 74,694 PSI (Min)

Yield Strength: 29,732 PSI (Min)

Elongation: 40%

Grade 316L

Tensile Strength: 70,343 PSI (Min)

Yield Strength: 24,656 PSI (Min)

Elongation: 40%

Typical Uses

Typical Applications for 316 include:

- Food Preparation Equipment

- Laboratory Benches & Equipment

- Coastal Architectural Paneling

- Boat Fittings

- Chemical Containers

- Heat Exchangers

- Threaded Fasteners

- Springs

|

|